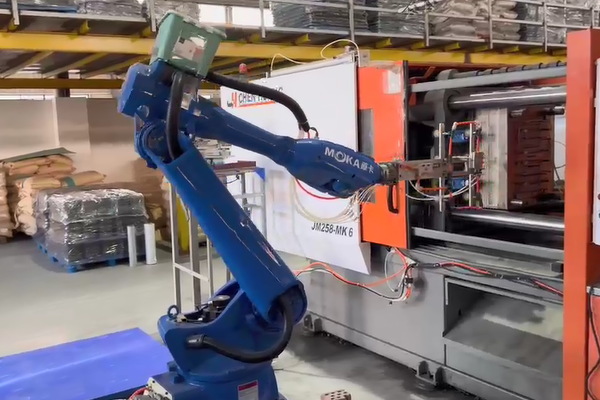

Transfer robots are industrial robots that can carry out automated handling operations. The first handling robots appeared in the United States in 1960, when two robots, Versatran and Unimate, were first used for handling operations. Handling refers to the use of one machine to hold the workpiece, which refers to moving from one machining position to another. The handling robot can install different end effectors to complete the workpiece handling work of various shapes and states, which greatly reduces the heavy physical labor of humans. Widely used in auto parts manufacturing, automobile production and assembly, mechanical processing, electronic and electrical, rubber and plastics, wood and furniture and other manufacturing industries, as well as pharmaceutical, food, beverage, chemical and other industries of transportation, packaging, packing, handling, palletizing and other work fields. Some developed countries have developed the maximum manual handling, and those exceeding the limit must be completed by handling robots.

Handling robot is a high-tech in the field of modern automatic control,

involving mechanics, mechanics, electrical hydraulic pressure

technology, automatic control technology, sensor technology, single-chip

microcomputer technology and computer technology and other disciplines,

has become an important part of modern machinery manufacturing

production system. Its advantage is that it can be programmed to

complete a variety of expected tasks, and it has the respective

advantages of man and machine in its own structure and performance,

especially artificial intelligence and adaptability.

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±170° | 480°/s |

| Axis 2L | -130° to +90° | 460°/s |

| Axis 3U | -60° to +205° | 520°/s |

| Axis 4R | ±190° | 560°/s |

| Axis 5B | ±120° | 560°/s |

| Axis 6T | ±360° | 880°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±170° | 300°/s |

| Axis 2L | -140° to +70° | 300°/s |

| Axis 3U | -75° to +200° | 400°/s |

| Axis 4R | ±190° | 550°/s |

| Axis 5B | ±130° | 560°/s |

| Axis 6T | ±360° | 975°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±170° | 300°/s |

| Axis 2L | -140° to +80° | 300°/s |

| Axis 3U | -75° to +200° | 400°/s |

| Axis 4R | ±190° | 550°/s |

| Axis 5B | ±130° | 560°/s |

| Axis 6T | ±360° | 975°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±180° | 202°/s |

| Axis 2L | +98° to -160° | 212°/s |

| Axis 3U | +200° to -80° | 270°/s |

| Axis 4R | ±200° | 470°/s |

| Axis 5B | ±130° | 405°/s |

| Axis 6T | ±360° | 650°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±180° | 202°/s |

| Axis 2L | +98° to -160° | 211°/s |

| Axis 3U | +200° to -80° | 234°/s |

| Axis 4R | ±200° | 470°/s |

| Axis 5B | ±130° | 405°/s |

| Axis 6T | ±360° | 535°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±180° | 202°/s |

| Axis 2L | +98° to -160° | 211°/s |

| Axis 3U | +200° to -80° | 210°/s |

| Axis 4R | ±200° | 420°/s |

| Axis 5B | ±125° | 285°/s |

| Axis 6T | ±360° | 410°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±180° | 120°/s |

| Axis 2L | +60° to -80° | 110°/s |

| Axis 3U | +95° to -80° | 115°/s |

| Axis 4R | ±210° | 190°/s |

| Axis 5B | ±125° | 185°/s |

| Axis 6T | ±360° | 280°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±180° | 120°/s |

| Axis 2L | +60° to -80° | 110°/s |

| Axis 3U | +95° to -80° | 115°/s |

| Axis 4R | ±210° | 190°/s |

| Axis 5B | ±125° | 150°/s |

| Axis 6T | ±360° | 220°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±180° | 120°/s |

| Axis 2L | +60° to -80° | 110°/s |

| Axis 3U | +95° to -80° | 115°/s |

| Axis 4R | ±210° | 190°/s |

| Axis 5B | ±125° | 135°/s |

| Axis 6T | ±360° | 220°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±167° | 223°/s |

| Axis 2L | +92°to-150° | 223°/s |

| Axis 3U | +110°to-85° | 214°/S |

| Axis 4R | ±150° | 370°/S |

| Axis 5B | +20°to-200° | 370°/S |

| Axis 6T | ±360° | 370°/S |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±160° | 216°/s |

| Axis 2L | +90°to-120° | 150°/s |

| Axis 3U | +140°to-70° | 175°/s |

| Axis 4R | ±190° | 378°/s |

| Axis 5B | +30°to-210° | 286°/s |

| Axis 6T | ±360° | 370°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±167° | 181°/s |

| Axis 2L | +92°to-150° | 181°/s |

| Axis 3U | +110°to-85° | 190°/s |

| Axis 4R | ±150° | 370°/s |

| Axis 5B | +20°to-200° | 370°/s |

| Axis 6T | ±360° | 370°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±160° | 133°/s |

| Axis 2L | +80°to-145° | 149°/s |

| Axis 3U | +145°to-75° | 149°/s |

| Axis 4R | ±190° | 315°/s |

| Axis 5B | +50°to-210° | 245°/s |

| Axis 6T | ±360° | 376°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±160° | 257°/s |

| Axis 2L | +80°to-145° | 223°/s |

| Axis 3U | +145°to-75° | 257°/s |

| Axis 4R | ±190° | 272°/s |

| Axis 5B | +50°to-210° | 275°/s |

| Axis 6T | ±360° | 540°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±160° | 200°/s |

| Axis 2L | +80°to-145° | 200°/s |

| Axis 3U | +145°to-75° | 300°/s |

| Axis 4R | ±190° | 375°/s |

| Axis 5B | +50°to-210° | 450°/s |

| Axis 6T | ±360° | 450°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±170° | 223°/s |

| Axis 2L | -32°to+80° | 173°/s |

| Axis 3U | +20°to-90° | 300°/s |

| Axis 4R | ±360° | 481°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±170° | 338°/s |

| Axis 2L | ±110° | 245°/s |

| Axis 3U | +70°to-90° | 300°/s |

| Axis 4R | ±200° | 262°/s |

| Axis 5B | ±120° | 376°/s |

| Axis 6T | ±360° | 600°/s |

telephone:400-800-5282

mobile:+86-18668266803

email:moka@moka-robot.com

website:www.moka-robot.com

address:No. 19, Weisi Road, Jiujiang District, Wuhu City, Anhui Province