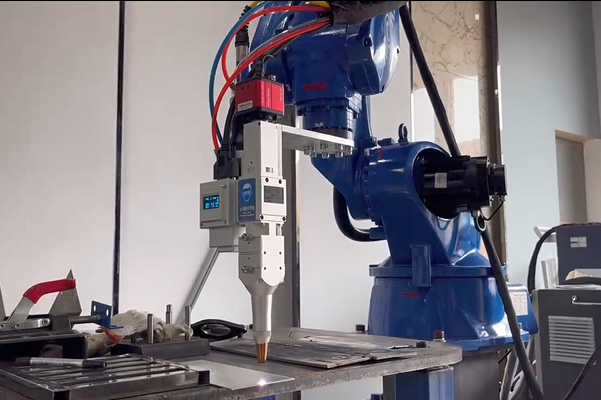

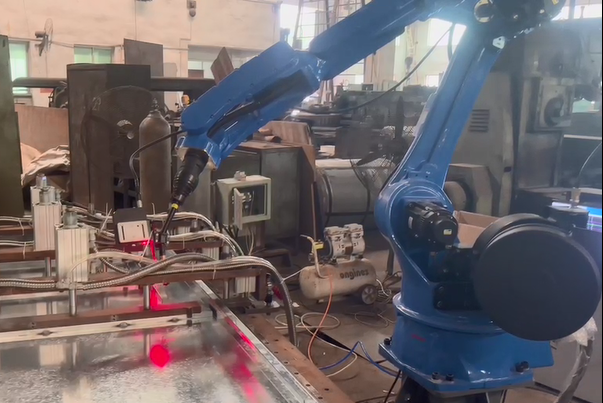

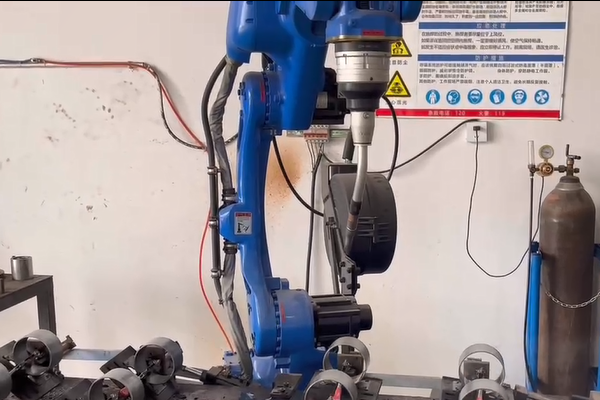

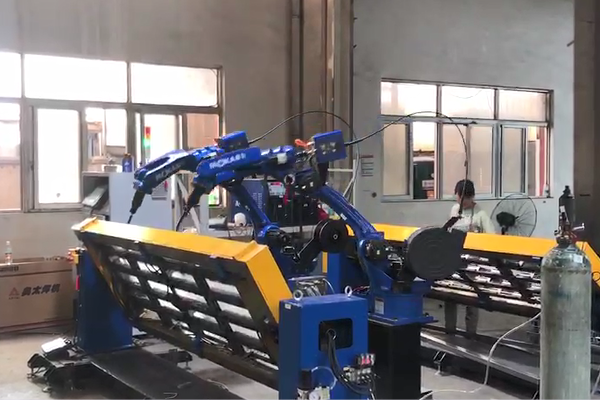

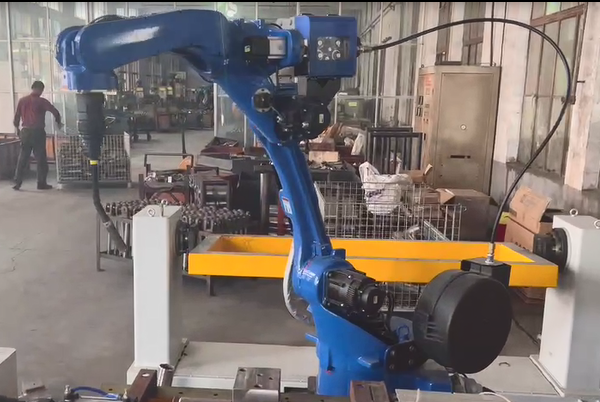

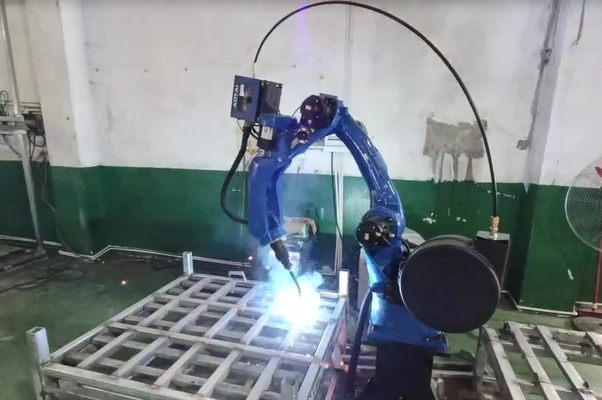

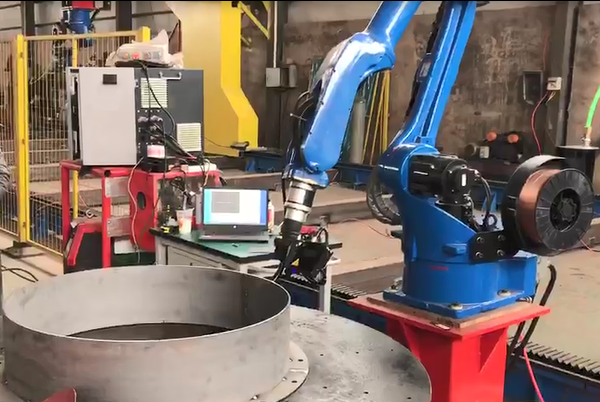

Welding robots are industrial robots engaged in welding (including cutting and spraying). According to the definition of the International Organization for Standardization (ISO) industrial robot is a standard welding robot, an industrial robot is a multi-purpose, reprogrammable automatic control manipulator (Manipulator), with three or more programmable axes for field of industrial automation. In order to adapt to different purposes, the mechanical interface of the last axis of the robot is usually a connecting flange, which can be connected to different tools or end effectors. The welding robot is equipped with welding tongs or welding (cutting) guns on the flange of the final axis of the industrial robot, so that it can perform welding, cutting or thermal spraying.

With the development of electronic technology, computer technology,

numerical control and robot technology, automatic welding robot has been

used in production since the 1960s, and its technology has become

increasingly mature. Therefore, it has been widely used in various

industries.

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±160° | 285°/s |

| Axis 2L | +80° to-145° | 247°/s |

| Axis 3U | +145° to-75° | 285°/s |

| Axis 4R | ±190° | 392°/s |

| Axis 5B | +50° to-210° | 272°/s |

| Axis 6T | ±220° | 1353°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±160° | 203°/s |

| Axis 2L | +80°to-145° | 203°/s |

| Axis 3U | +145°to-75° | 214°/s |

| Axis 4R | ±190° | 392°/s |

| Axis 5B | +50°to-210° | 276°/s |

| Axis 6T | ±220° | 1356°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±160° | 203°/s |

| Axis 2L | +80°to-145° | 203°/s |

| Axis 3U | +145°to-75° | 181°/s |

| Axis 4R | ±190° | 353°/s |

| Axis 5B | +50°to-210° | 276°/s |

| Axis 6T | ±220° | 600°/s |

| Axis | Range Of Motion | Movement Speed |

|---|---|---|

| Axis 1S | ±160° | 149°/s |

| Axis 2L | +80°to-145° | 125°/s |

| Axis 3U | +145°to-75° | 149°/s |

| Axis 4R | ±190° | 314°/s |

| Axis 5B | +50°to-210° | 245°/s |

| Axis 6T | ±220° | 1216°/s |

telephone:400-800-5282

mobile:+86-18668266803

email:moka@moka-robot.com

website:www.moka-robot.com

address:No. 19, Weisi Road, Jiujiang District, Wuhu City, Anhui Province